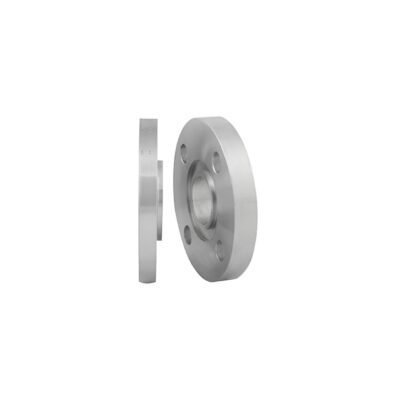

Alloy steel Ring Type Joint (RTJ) flanges are specifically designed for high-pressure and high-temperature applications where a reliable and leak-proof seal is critical. These flanges feature a distinctive groove that accommodates a ring gasket, usually made from alloy steel or other high-strength materials, to provide a secure and resilient seal. The RTJ flange design includes a precision-machined groove that allows for a metal-to-metal seal, enhancing its ability to handle extreme operating conditions. Typically made from alloy steels such as ASTM A182 F5, F9, or F11, these flanges meet stringent standards like ANSI/ASME B16.5 and B16.47, ensuring compatibility and performance in demanding environments. Applications are prevalent in industries such as oil and gas, chemical processing, and power generation, where safety and integrity are paramount.

| Property | Details |

|---|---|

| Material | Alloy Steel (e.g., ASTM A182 F5, F9, F11) |

| Standards | ANSI/ASME B16.5, B16.47 |

| Type | Ring Type Joint (RTJ) Flange |

| Flange Dimensions | Sizes from 1″ to 24″ and larger |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 650°C (1200°F) for high-alloy steels |

| Surface Finish | Smooth, precision-machined groove |

| Connection Type | Flanged connection with RTJ gasket |

| Design | Circular flange with a precision-machined groove for RTJ gasket |

| Advantages | Provides a leak-proof seal, suitable for high-pressure applications |

| Applications | Oil and gas pipelines, chemical processing, power generation |

| Manufacturing | Hot or cold rolled, precision-machined |

| Ordering Information | Specify material grade, size, pressure class, and standard |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.