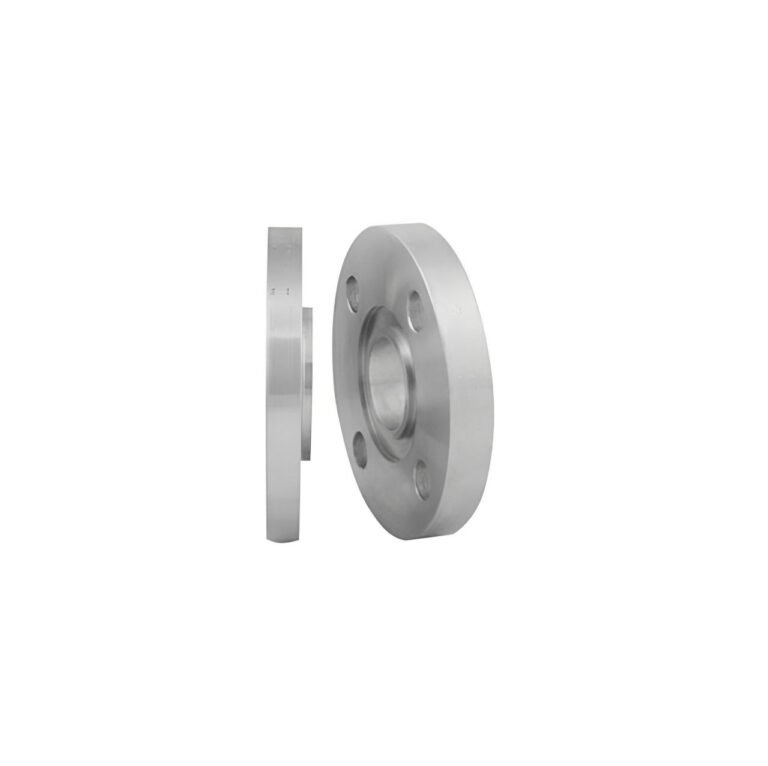

Alloy steel plate flanges are flat, circular flanges designed to be welded onto the end of a pipe or fitting to connect it to another component. Made from high-strength alloy steels such as ASTM A182 F11, F22, and A350 LF2, these flanges offer enhanced durability, high tensile strength, and resistance to harsh environmental conditions. They are often used in high-pressure and high-temperature applications where the mechanical properties of alloy steel provide added reliability. Plate flanges come in various sizes and pressure ratings, typically conforming to standards such as ANSI/ASME B16.5 and B16.47. The flange is flat with a bolt hole pattern that aligns with matching flanges for secure bolting. Common applications include oil and gas pipelines, chemical processing, and power generation systems where robust and reliable connections are required.

| Property | Details |

|---|---|

| Material | Alloy Steel (e.g., ASTM A182 F11, A182 F22, A350 LF2) |

| Standards | ANSI/ASME B16.5, B16.47 |

| Type | Plate Flange |

| Flange Dimensions | Sizes from 1″ to 24″ and larger |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 650°C (1200°F) for high-alloy steels |

| Surface Finish | Smooth, sometimes with a raised face (RF) |

| Connection Type | Welded connection |

| Design | Flat circular flange with bolt holes |

| Advantages | Strong, reliable connection, suitable for high-pressure applications |

| Applications | Oil and gas pipelines, chemical processing, power generation |

| Manufacturing | Hot or cold rolled, heat-treated |

| Ordering Information | Specify material grade, size, pressure class, and standard |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.