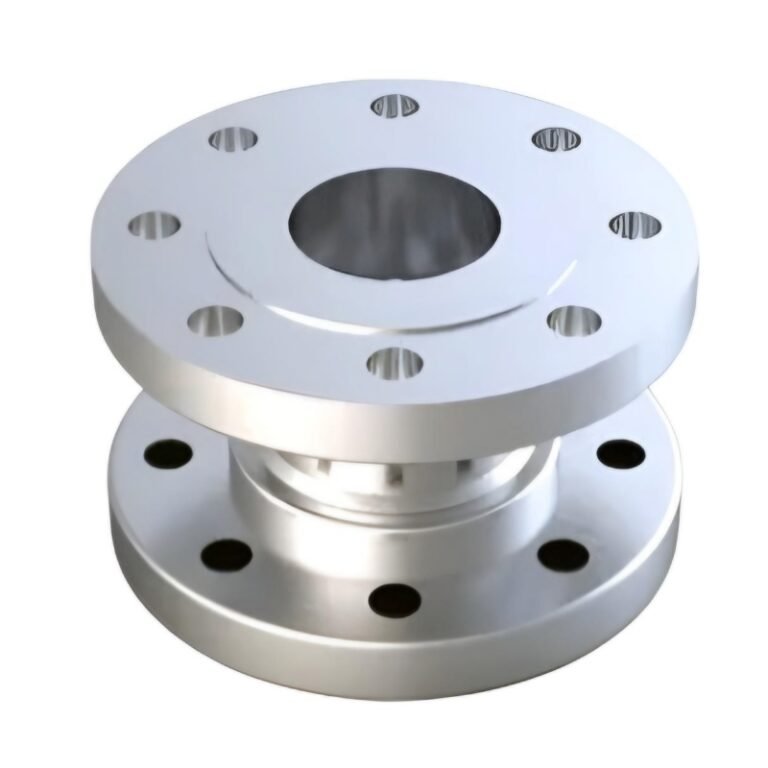

Alloy steel long weld neck flanges are designed for applications requiring robust and reliable connections in high-pressure and high-temperature environments. These flanges have an extended neck that provides a gradual transition between the flange and the pipe, which helps in distributing stress more evenly and reducing the potential for fatigue failure. Made from high-strength alloy steels such as ASTM A182 F11, F22, and A350 LF2, they offer excellent performance and durability under severe conditions. The long neck design also facilitates a smooth and continuous weld to the pipe, ensuring a secure and leak-proof joint. Commonly used in industries like oil and gas, chemical processing, and power generation, these flanges are ideal for critical applications where the integrity of the connection is crucial.

| Property | Details |

|---|---|

| Material | Alloy Steel (e.g., ASTM A182 F11, A182 F22, A350 LF2) |

| Standards | ASTM A182, ASTM A350 |

| Type | Long Weld Neck Flange |

| Flange Dimensions | Sizes typically from 1″ to 24″ |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 650°C (1200°F) for high-alloy steels |

| Surface Finish | Smooth, sometimes with a raised face (RF) |

| Connection Type | Welded connection |

| Neck Length | Extended neck for gradual transition |

| Advantages | Stress distribution, leak-proof, durable, easy alignment |

| Applications | Oil and gas, chemical processing, power generation |

| Manufacturing | Forged or cast, heat-treated |

| Ordering Information | Specify material grade, size, pressure class, and standard |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.