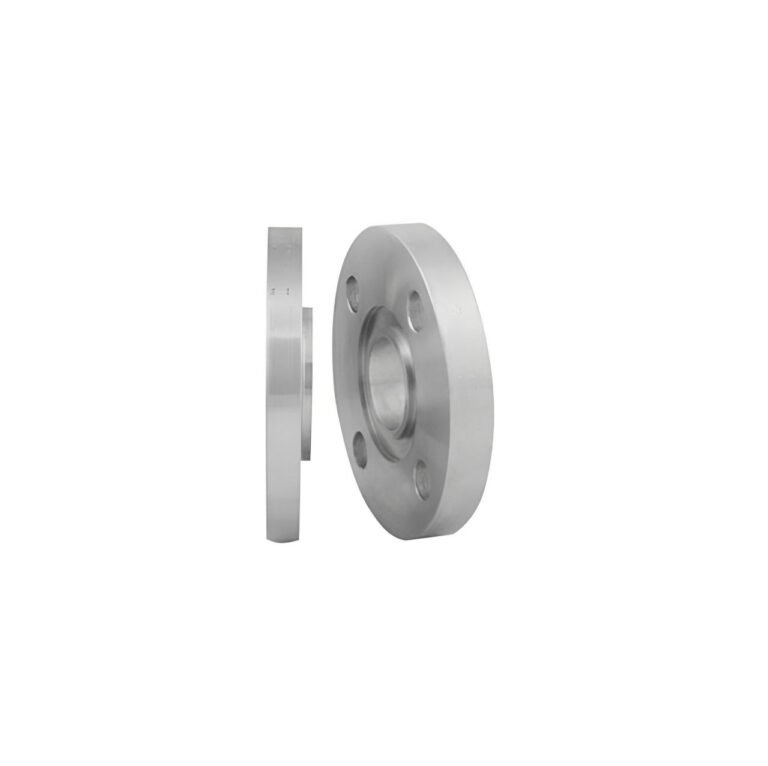

Alloy steel blind flanges are used to close the end of a pipe or vessel, effectively blocking the flow through a particular section of the piping system. These flanges are designed with a solid, flat surface that is bolted to the flange, creating a secure seal and preventing any leakage. Made from high-strength alloy steels, such as ASTM A182 F11, F22, and A350 LF2, these flanges are capable of withstanding high pressures and temperatures, as well as providing excellent resistance to wear and corrosion. Blind flanges are commonly utilized in various industries including oil and gas, chemical processing, and power generation, where robust and reliable sealing is essential. Their design allows for easy maintenance and future expansion of the piping system.

| Property | Details |

|---|---|

| Material | Alloy Steel (e.g., ASTM A182 F11, A182 F22, A350 LF2) |

| Standards | ASTM A182, ASTM A350 |

| Type | Blind Flange |

| Flange Dimensions | Sizes typically from 1″ to 24″ |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 650°C (1200°F) for high-alloy steels |

| Surface Finish | Smooth, sometimes with a raised face (RF) |

| Connection Type | Blind, bolted connection |

| Advantages | Provides a secure seal, high pressure and temperature resistance |

| Applications | Oil and gas, chemical processing, power generation |

| Manufacturing | Forged or cast, heat-treated |

| Ordering Information | Specify material grade, size, pressure class, and standard |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.