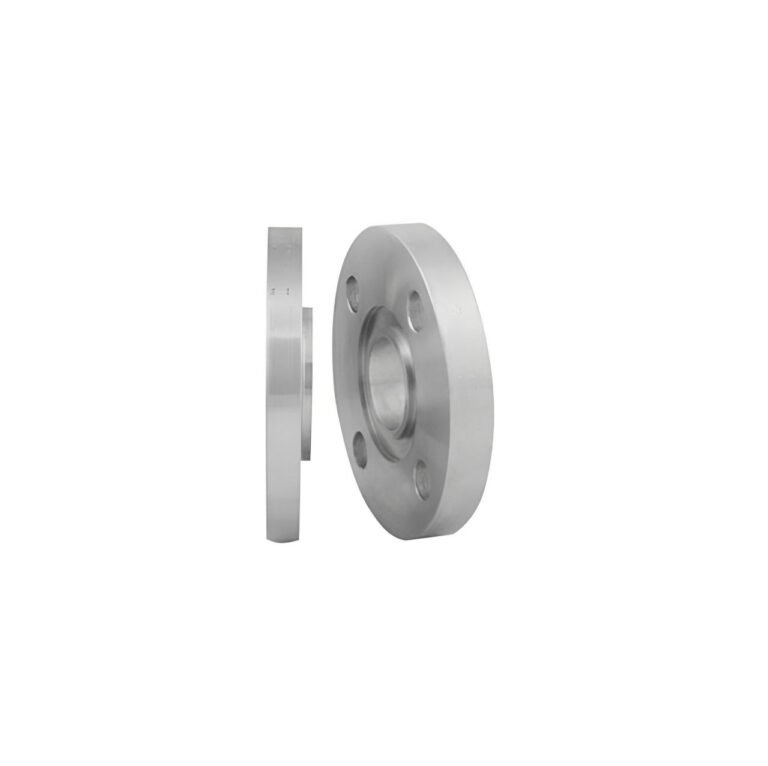

ASTM A182 F5 alloy steel weld neck flanges are designed for high-pressure and high-temperature applications, offering a reliable and robust connection between pipes. Made from ASTM A182 F5 alloy steel, these flanges are renowned for their high strength, durability, and resistance to thermal and mechanical stresses. The weld neck design features a long, tapered hub that provides a smooth transition between the flange and the pipe, reducing stress concentrations and improving the strength of the connection. These flanges are commonly used in industries such as petrochemical, oil and gas, and power generation, where robust and leak-proof connections are crucial. Adhering to standards such as ANSI/ASME B16.5, these flanges ensure compatibility and a secure fit in various high-pressure systems. The weld neck flange’s design also facilitates easy alignment and welding, making it a preferred choice for critical applications.

| Property | Details |

|---|---|

| Material | ASTM A182 F5 Alloy Steel |

| Standards | ANSI/ASME B16.5 |

| Type | Weld Neck Flange |

| Flange Dimensions | Custom sizes available |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 550°C (1022°F) for ASTM A182 F5 |

| Surface Finish | Smooth, precision-machined |

| Design | Tapered hub for smooth transition |

| Advantages | High strength, leak-proof, easy alignment and welding |

| Applications | Petrochemical, oil and gas, power generation |

| Manufacturing | Hot or cold rolled, precision-machined |

| Ordering Information | Specify material grade, size, pressure class |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.