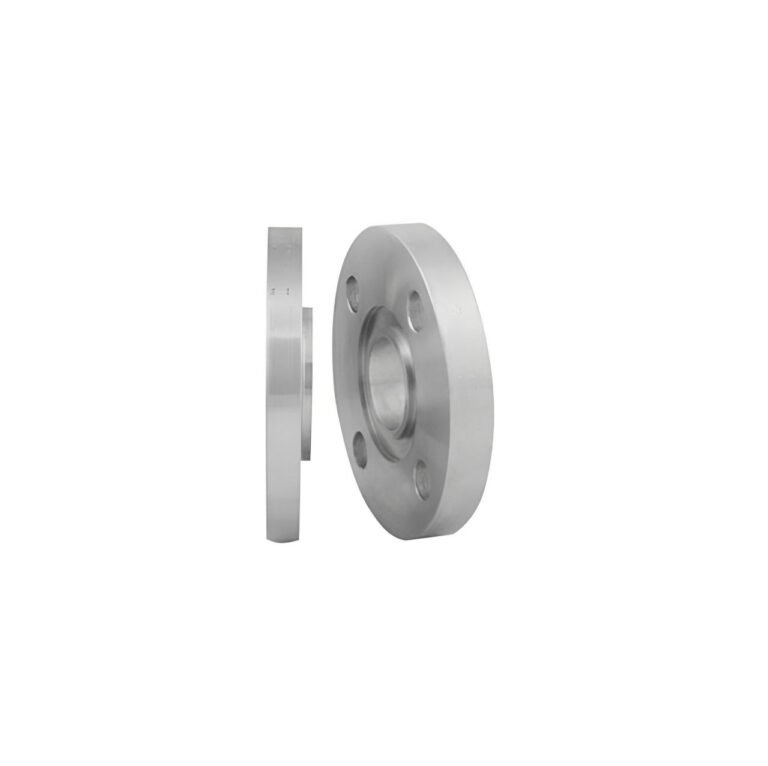

ASTM A182 F5 alloy steel lap joint flanges are specifically designed for applications where a bolted connection is necessary but frequent disassembly and maintenance are required. These flanges, made from ASTM A182 F5 alloy steel, offer high strength and durability under extreme temperatures and pressures. The lap joint design allows for the flange to be mounted on a stub end, making it ideal for applications where ease of alignment and removal is essential. The flange features a smooth, flat face that helps in creating a secure seal when bolted to another component. Due to their construction, lap joint flanges are less prone to deformation and can handle high-stress applications effectively. They adhere to ANSI/ASME B16.5 standards for compatibility with other pipeline components. These flanges are commonly used in the oil and gas industry, petrochemical industries, and power generation systems, where reliability and frequent maintenance are crucial.

| Property | Details |

|---|---|

| Material | ASTM A182 F5 Alloy Steel |

| Standards | ANSI/ASME B16.5 |

| Type | Lap Joint Flange |

| Flange Dimensions | Custom sizes available |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 550°C (1022°F) for ASTM A182 F5 |

| Surface Finish | Smooth, precision-machined |

| Design | Flat face for bolting onto a stub end |

| Advantages | Easy alignment, removable, reduces flange face wear |

| Applications | Oil and gas, petrochemical, power generation |

| Manufacturing | Precision-machined for accurate dimensions |

| Ordering Information | Specify material grade, size, pressure class |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.