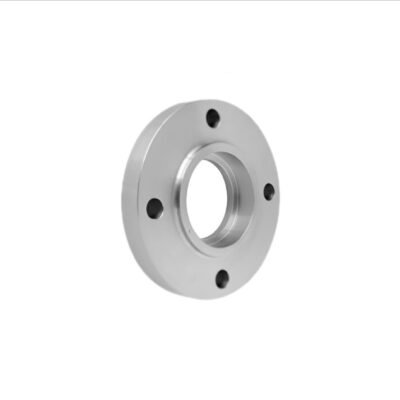

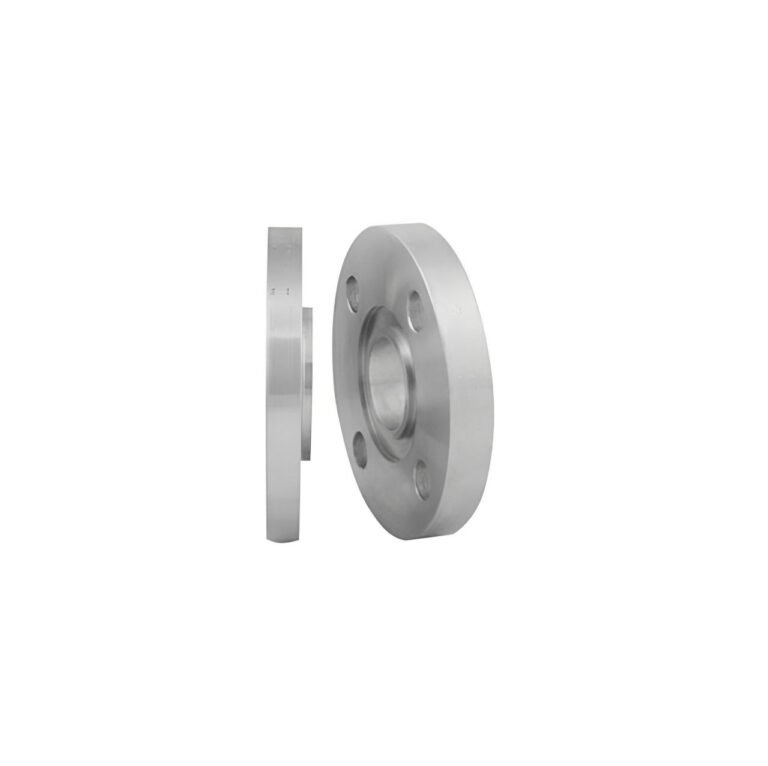

Alloy steel slip-on flanges are fittings used to connect pipes or other components in a piping system. They are designed with a slip-on feature that allows them to slide over the pipe before being welded into place. This design simplifies the alignment process, making them easier to install compared to weld neck flanges. Made from various alloy steels, these flanges offer improved mechanical properties, such as higher strength, toughness, and resistance to wear and corrosion, compared to standard carbon steels. Alloy steel slip-on flanges are often used in high-pressure and high-temperature applications in industries such as oil and gas, chemical processing, and power generation. Their ability to withstand harsh conditions and maintain structural integrity makes them a reliable choice for demanding environments.

| Property | Details |

|---|---|

| Material | Alloy Steel (e.g., ASTM A105, A182 F11, A182 F22, A350 LF2) |

| Standards | ASTM A105, ASTM A182, ASTM A350 |

| Type | Slip-On Flange |

| Flange Dimensions | Various sizes available, commonly from 1″ to 24″ |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500, Class 2500 |

| Temperature Rating | Up to 650°C (1200°F) for high-alloy steels |

| Surface Finish | Smooth, sometimes with a raised face (RF) |

| Connection Type | Slip-on, weld to pipe |

| Advantages | Easy alignment, reduced installation time, suitable for high-pressure applications |

| Applications | Oil and gas, chemical processing, power generation |

| Manufacturing | Forged or cast, heat-treated |

| Ordering Information | Specify material grade, size, pressure class, and standard |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.