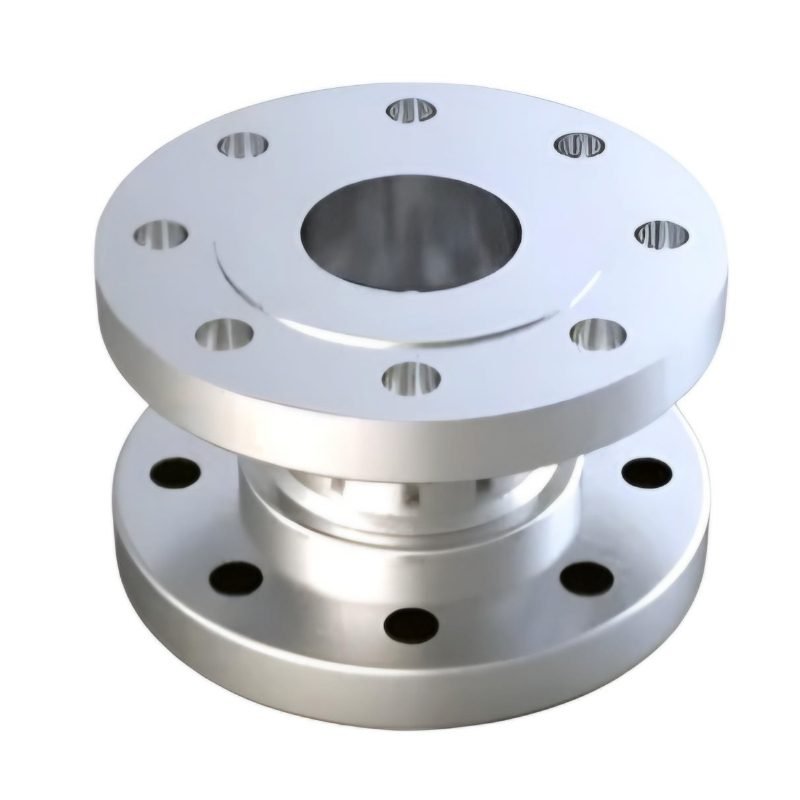

B2 Flanges are highly versatile components widely employed across diverse industries such as Off-Shore Oil Drilling, Petrochemicals, Chemical Equipment, Condensers, and Power Generation, among others. Known for their excellent fabricability, sturdy structure, and high ductility, these flanges offer superior surface finish and extended working life. They exhibit remarkable resistance to rust, corrosion, and various chemical substances including hydrogen chloride gas, sulfuric acid, acetic acid, and phosphoric acid, making them ideal for challenging environments. With their ability to maintain flexibility even under elevated pressure and temperature conditions, B2 Flanges ensure reliable performance in demanding applications, including those requiring resistance to hydrochloric acid across a wide range of temperatures.

| Feature | Description |

| Grade | Alloy B2 |

| Features | Excellent fabricability, sturdy structure, high ductility, excellent tensile strength, superior surface finish, longer working life |

| Rust Resistance | Rust-free mechanism |

| Flexibility | Higher flexibility at elevated pressure and temperature conditions |

| Chemical Resistance | Hydrogen chloride gas, sulfuric acid, acetic acids, phosphoric acid, hydrochloric acid (high & low temperatures) and chemical solutions |

Reviews

Clear filtersThere are no reviews yet.