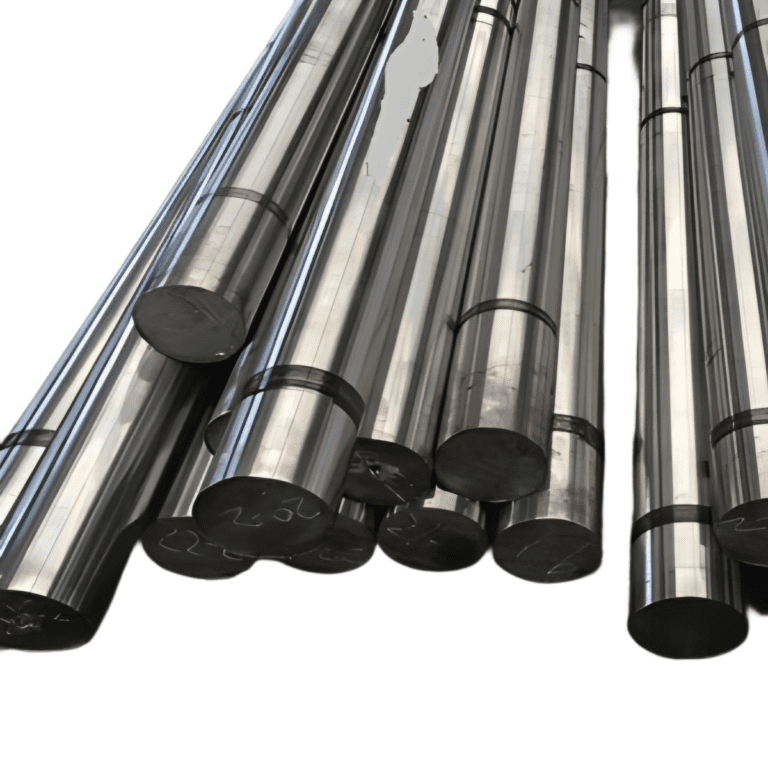

Elevate your piping systems’ corrosion resistance and performance with Alloy 20 buttweld fittings, specifically engineered for applications requiring excellent resistance to a wide range of corrosive environments. Alloy 20, also known as Carpenter 20, is a nickel-iron-chromium alloy with additions of copper and molybdenum, offering superior resistance to sulfuric acid, phosphoric acid, chloride stress corrosion cracking, and pitting. Upgrade your piping systems with Alloy 20 buttweld fittings to benefit from their exceptional corrosion resistance, versatility, and reliability in corrosive environments. These fittings are well-suited for critical applications in chemical processing, pharmaceutical, food processing, marine, and other industries where resistance to corrosion is paramount.

| Attribute | Details |

| Grade | Alloy 20 |

| Standard | ASTM B366 |

| Types | Elbows |

| Size Range | 1/4″ and Larger |

| High-Temperature | Performance Suitable for elevated temperature applications up to 1000°F (538°C) |

| Corrosion Resistance | Excellent resistance to sulfuric acid, phosphoric acid, chloride stress corrosion cracking, and pitting |

| Material Composition | Nickel-Iron-Chromium Alloy with Copper and Molybdenum |

| Applications | Chemical Processing, Pharmaceutical, Food Processing, Marine, and more |

| Tensile Strength | ≥80,000 psi (550 MPa) |

| Yield Strength | ≥35,000 psi (240 MPa) |

Reviews

Clear filtersThere are no reviews yet.