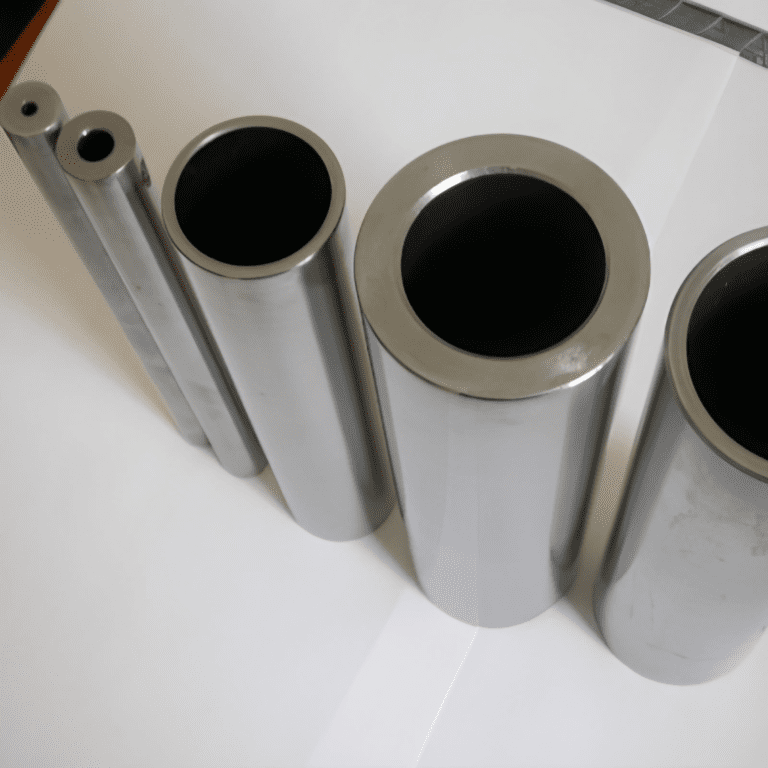

Upgrade your industrial piping systems with Grade 825 nickel alloy buttweld fittings, meticulously crafted from a corrosion-resistant nickel-iron-chromium-molybdenum alloy designed to excel in aggressive environments. Grade 825 fittings offer exceptional corrosion resistance, mechanical strength, and durability, making them ideal for critical installations across various industries. your piping systems with Grade 825 nickel alloy buttweld fittings to benefit from their superior corrosion resistance, mechanical strength, and reliability in challenging industrial environments. These fittings are designed to withstand corrosive media, high temperatures, and mechanical stresses, ensuring optimal performance and longevity in critical applications.

| Attribute | Details |

| Grade | 825 |

| Standard | ASTM B366/B366M, ASME SB366 |

| Types | Stub Ends |

| Material Composition | Nickel (38-46%), Iron (22-30%), Chromium (19.5-23.5%), Molybdenum (2.5-3.5%), Copper (1.5-3%), with additions of titanium, aluminum, and other elements |

| Size Range | 1/2″ and larger |

| Tensile Strength | Minimum 80 ksi (550 MPa) |

| Yield Strength | Minimum 40 ksi (275 MPa) |

| Corrosion Resistance | Outstanding resistance to sulfuric acid, phosphoric acid |

| High-Temperature | at temperatures up to approximately 550°C (1022°F) |

| Performance | Performance Maintains superior mechanical properties |

| Applications | Chemical processing, marine, offshore, desalination plants, power generation |

| Benefits | Corrosion resistance, high-temperature stability, durability |

Reviews

Clear filtersThere are no reviews yet.