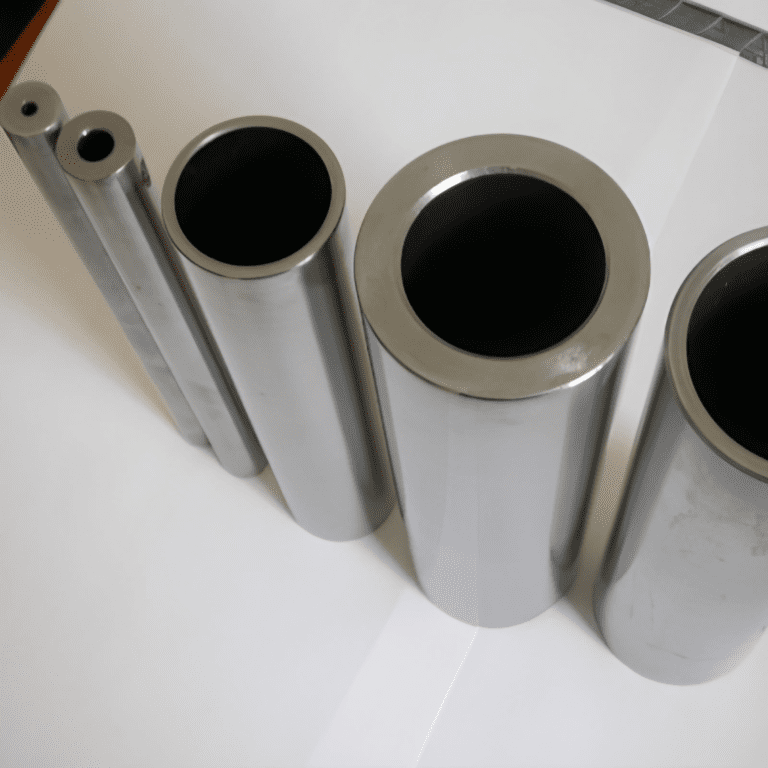

825 pipes and tubes, crafted from 825 (UNS N08825), are an austenitic grade alloy, feature iron, chromium, and nickel, and minor additions of molybdenum, titanium, and copper. Engineered to offer exceptional resistance across various corrosive environments, including oxidizing and reducing conditions, these components exhibit superior performance. Their nickel content ensures resilience against chloride stress corrosion cracking, while the combination of molybdenum and copper enhances corrosion resistance in reducing environments compared to standard grades. With a chemical composition ranging from 19.5% to 23.5% Chromium (Cr), 1.5% to 3% Copper (Cu), 2.5% to 3.5% Molybdenum (Mo), and other elements within specified limits, these pipes and tubes provide robustness and reliability. The hot working temperature range for 825 tubes and pipes spans from 1600°F to 2150°F (870°C to 1180°C), with optimal corrosion resistance achieved through hot working temperatures between 1600°F and 1800°F (870°C and 980°C), followed by rapid cooling.

| Attribute | Specification |

|---|---|

| Grade | 825 |

| Standards | ASTM, ASME |

| Sizes | 1/8″ to 64″ |

| Chemical Composition | Chromium (Cr): 19.5% – 23.5% |

| Copper (Cu): 1.5% – 3% | |

| Molybdenum (Mo): 2.5% – 3.5% | |

| Hot Working Temperature Range | 1600°F to 2150°F (870°C to 1180°C) |

Reviews

Clear filtersThere are no reviews yet.