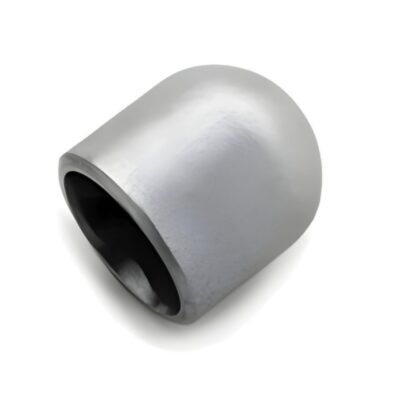

Upgrade your industrial piping systems with Grade 625 nickel alloy buttweld fittings, meticulously crafted from a versatile nickel-based alloy known for exceptional corrosion resistance, high-temperature performance, and mechanical strength. These fittings conform to ASTM B366/B366M and ASME SB366 specifications, ensuring high-quality fabrication and dimensional accuracy. Available in a comprehensive range of types including elbows, tees, reducers, caps, and stub ends, Grade 625 fittings come in sizes ranging from 1/2″ to 12″ and larger, meeting diverse piping requirements. The buttweld design facilitates strong, leak-free connections, enhancing system integrity. Grade 625 nickel alloy fittings exhibit impressive mechanical properties, with a minimum tensile strength of 120 ksi (827 MPa) and a minimum yield strength of 60 ksi (414 MPa), suitable for high-pressure and high-stress applications. They offer exceptional corrosion resistance to seawater, acids, alkalis, and oxidizing chemicals, making them ideal for chemical processing, marine, offshore, and aerospace industries.

| Attribute | Details |

| Grade | 625 |

| Standard | ASTM B366/B366M, ASME SB366 |

| Types | Reducers |

| Size Range | 1/2″ and larger |

| Material Composition | Nickel (58%), Chromium (20-23%), Molybdenum (8-10%), Niobium (3.15-4.15%), with smaller amounts of iron, titanium, aluminum, and other elements |

| Tensile Strength | Minimum 120 ksi (827 MPa) |

| Temperature Performance | approximately 980°C (1800°F) |

| Corrosion Resistance | Excellent resistance to seawater, acids, alkalis, and oxidizing chemicals |

| Applications | Chemical processing, marine, offshore, aerospace, power generation |

| Benefits | Corrosion resistance, high-temperature performance, durability, reliability |

Reviews

Clear filtersThere are no reviews yet.