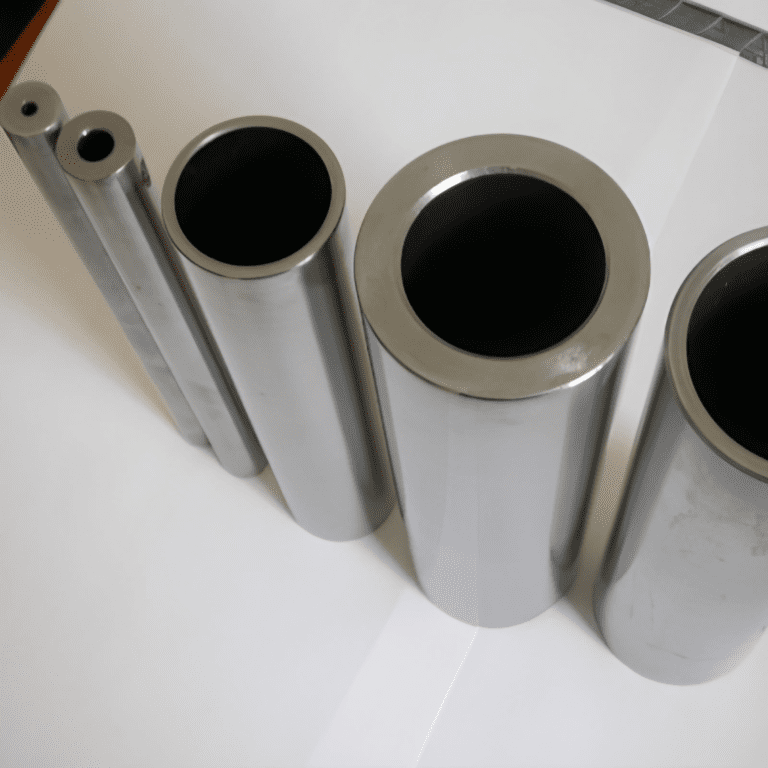

5083 Aluminum Pipe is a versatile alloy widely used across industries. The ASTM B241 Aluminum Seamless Pipe boasts a smooth surface and fine granular structure, ideal for precise anodizing. With added magnesium and other elements, it offers superior corrosion resistance, making it a top choice for marine applications. While not as strong as steel, the Aluminum 5083 Box Pipes, known for their strength, serve demanding applications. The EN AW-5083 Aluminum Welded Pipe, a non-heat treatable alloy, gains strength through cold working. Its electric resistance welding capability ensures good weldability, facilitating its interchangeability with other materials. Various shapes like round, square, and rectangular cater to different needs, with wall thickness and nominal sizes influencing strength. The 5083 Grade Aluminum Schedule 40 Pipes are particularly favored in marine settings, balancing strength and corrosion resistance for optimal performance.

| Attribute | Description |

|---|---|

| Material | 5083 Aluminum |

| Standard | ASTM B241 (Seamless), EN AW-5083 (Welded) |

| Surface | Smooth surface, fine granular structure |

| Corrosion Resistance | Excellent corrosion resistance, especially in marine environments |

| Shape | Various shapes available including round, square, and rectangular |

| Strength | Not as strong as steel, but offers sufficient strength for many applications |

| Weldability | Good weldability, suitable for electric resistance welding (ERW) |

| Heat Treatment | Non-heat treatable alloy, gains strength through cold working |

| Application | Widely used in marine applications and other industries |

Reviews

Clear filtersThere are no reviews yet.