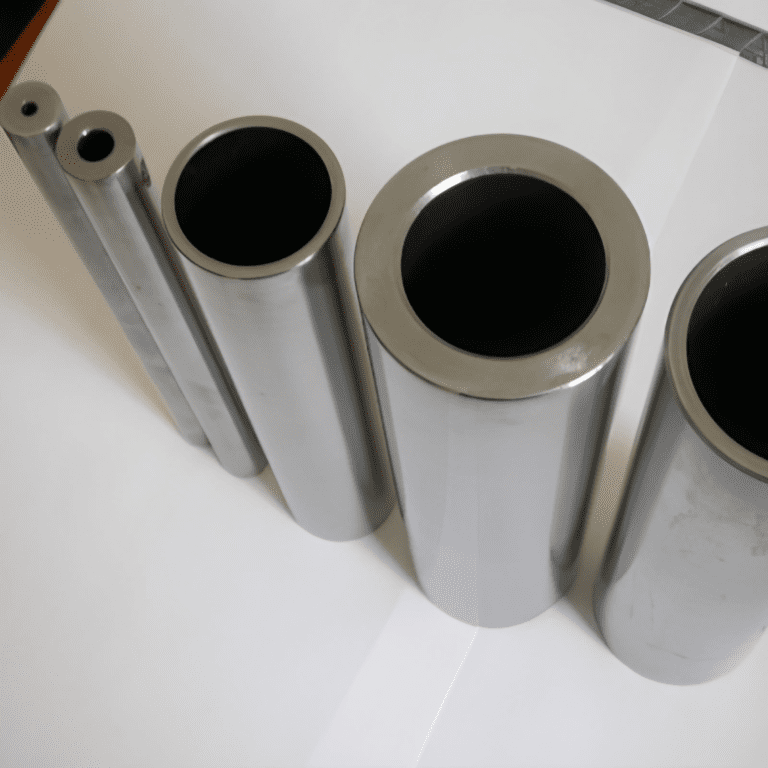

C22.8 Carbon Steel is among the most widely used plain carbon steels, boasting approximately 0.65% manganese and a nominal carbon content of 0.22%. Renowned for its excellent combination of ductility and strength, C22.8 may be hardened or carburized, making it suitable for moderate strength structural applications, often utilized in the case hardened condition. Specifically, it serves as a standard specification for steel flanges intended for pressure systems across diverse industries, including chemical, petroleum, and natural gas. C22.8 flanges are engineered to withstand high-pressure and high-temperature environments, available in various sizes and types such as weld neck, slip-on, threaded, lap joint, and blind flanges. Manufactured from carbon steel, these flanges are typically coated with rust-resistant materials to mitigate corrosion risks. The C22.8 standard mandates requirements for dimensions, material, design, marking, and testing, ensuring compliance with specific pressure and temperature ratings. Before installation, these flanges undergo rigorous testing to ensure adherence to industry standards. Widely utilized across oil and gas, chemical, and petrochemical industries, C22.8 flanges find application in pipelines, refineries, chemical processing plants, and more, owing to their reliability and durability in demanding environments.

| Feature | Description |

|---|---|

| Grade | C22.8 |

| Standard | ASTM |

| Available Sizes | Ranges from 1/4” to any size |

| Manganese Content | Approximately 0.65% |

| Carbon Content | Nominal content of 0.22% |

Reviews

Clear filtersThere are no reviews yet.