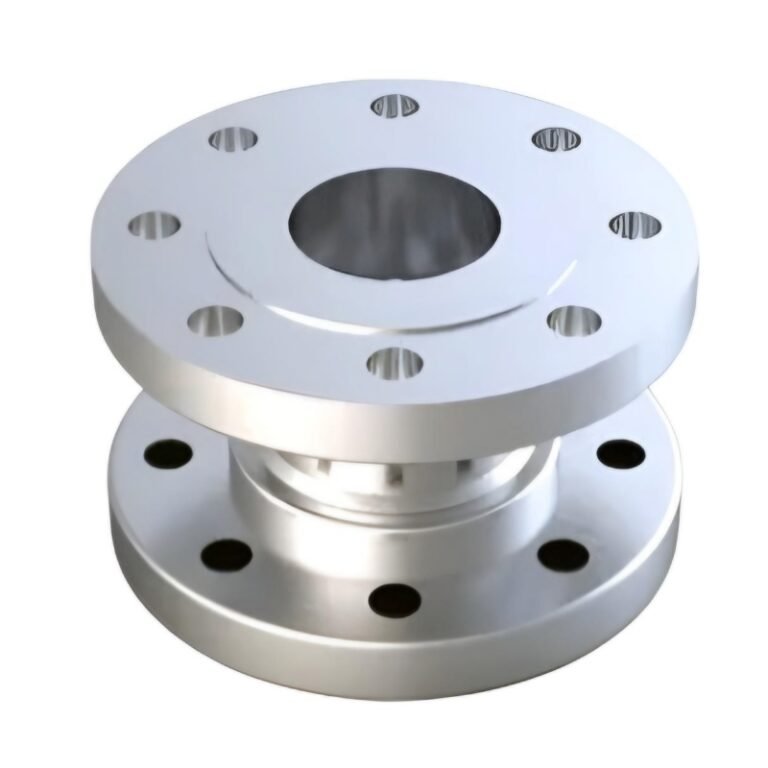

ASTM A182 Fg alloy steel tongue and groove flanges are designed for applications requiring a secure and tight seal under high-pressure and high-temperature conditions. The tongue and groove design involves a flange with a protruding “tongue” that fits into a matching “groove” of another flange, creating a more robust and leak-resistant connection compared to flat-faced flanges. This design helps in aligning the flanges accurately and provides a better seal when used with a gasket. Fg alloy steel, known for its strength and corrosion resistance, makes these flanges suitable for demanding environments in industries such as petrochemical, oil and gas, and power generation. The flanges are manufactured to precise standards to ensure durability and performance in critical applications.

| Property | Details |

|---|---|

| Material | Grade Fg Alloy Steel |

| Standards | ASTM A182, ANSI/ASME B16.5 |

| Type | Tongue & Groove Flange |

| Dimensions | Custom sizes available |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 593°C (1100°F) for Grade Fg |

| Surface Finish | Smooth, precision-machined |

| Tongue & Groove Design | Protruding tongue and matching groove |

| Thickness | As per ANSI/ASME standards |

| Applications | Petrochemical, power generation, oil and gas |

| Advantages | Enhanced alignment, secure seal |

| Function | Ensuring leak-proof and robust connections |

| Manufacturing | Precision-machined for accurate dimensions |

| Ordering Information | Specify material grade, size, pressure class |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.