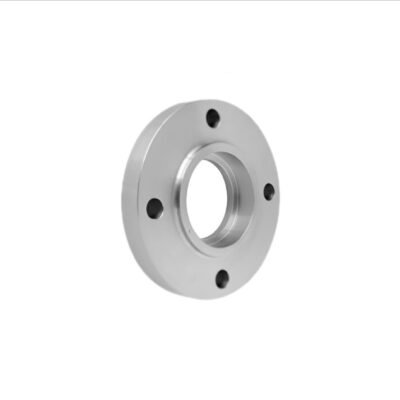

ASTM A182 F5 alloy steel blind flanges are integral components used to close the ends of piping systems, effectively sealing them and preventing the flow of fluids. Made from ASTM A182 F5 alloy steel, these blind flanges are designed to withstand high temperatures and pressures, making them suitable for demanding industrial applications. The blind flange does not have a central hole, making it ideal for applications where a pipeline needs to be shut off, or future connections are anticipated. These flanges adhere to standards such as ANSI/ASME B16.5, ensuring compatibility and reliability in various high-pressure and high-temperature settings. The F5 alloy steel provides superior strength and durability, which is essential in environments subject to thermal and mechanical stresses. The precision machining of these flanges ensures a tight seal and a reliable connection. Blind flanges are widely used in sectors including petrochemical, oil and gas, and power generation.

| Property | Details |

|---|---|

| Material | ASTM A182 F5 Alloy Steel |

| Standards | ANSI/ASME B16.5 |

| Type | Blind Flange |

| Flange Dimensions | Custom sizes available |

| Pressure Rating | Class 150, Class 300, Class 600, Class 900, Class 1500 |

| Temperature Rating | Up to 550°C (1022°F) for ASTM A182 F5 |

| Surface Finish | Smooth, precision-machined |

| Design | Solid disc with no central hole |

| Advantages | Effective sealing, prevents flow, high pressure tolerance |

| Applications | Petrochemical, oil and gas, power generation |

| Manufacturing | Hot or cold rolled, precision-machined |

| Ordering Information | Specify material grade, size, pressure class |

| Suppliers | McMaster-Carr, Grainger, Swagelok, Penn Stainless Products |

Reviews

Clear filtersThere are no reviews yet.